top of page

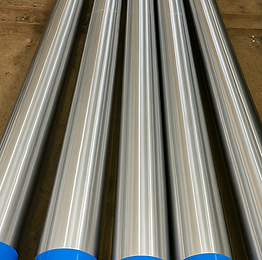

H13 | DIN 2344 | AISI H13

Key Features

-

Excellent Hot Hardness and Toughness

-

Good Wear Resistance in Hot condition

-

Good machinability for complex tooling

-

Versatile tool applications

Size Range

Round Bar

80 mm To 400 mm Diameter

Flat Bar

80mm*80mm To 550mm*205mm

About the Steel

H13 tool steel is a versatile chromium-molybdenum hot work steel known for its exceptional performance under high thermal and mechanical stress. It offers a unique balance of hardness, toughness, and wear resistance, making it highly resistant to thermal fatigue, cracking, and distortion during heat cycling. H13 maintains its strength at elevated temperatures and responds well to heat treatment, offering long tool life in demanding conditions. Its stable behavior during hardening and excellent resistance to abrasion and impact make it a preferred choice for tooling in hot work environments.

Applications

-

Extrusion Dies & Mandrels

Retains shape and strength during high-temperature metal extrusion.

-

Hot Shear Blades

Maintains sharpness and integrity under continuous hot cutting.

-

Die Casting Molds

Resists thermal fatigue and erosion from molten metal flow.

-

Core Pins & Mold Inserts

Provides dimensional stability and wear resistance in tool cavities.

Manufacturing

Process flow for manufacturing H13 steel

Melting

Ingots melted in EIF, impurities fully killed and followed LRF and VD process at Client's request. Ingots annealed

Forging

Press Forged with reduction ratio of 3.75 to 5 times

Heat Treatment

Full annealing cycle post forging

Quality Test

Ultrasonic, Hardness, Mechanical, Microstructure testing of the metal at a NABL approved lab

Proof Machining

Proof machining of Forged Rounds and Flats as per Client's requirements

bottom of page