top of page

SS304L | 1.4307 | 304L

Key Features

-

Excellent Corrosion Resistance

-

Versatile & Widely Used Alloy

-

Good Weldability & Formability

-

High Ductility & Toughness

Size Range

Round Bar

80 mm To 500 mm Diameter

Flat Bar

80mm*80mm To 510mm*360mm

About the Steel

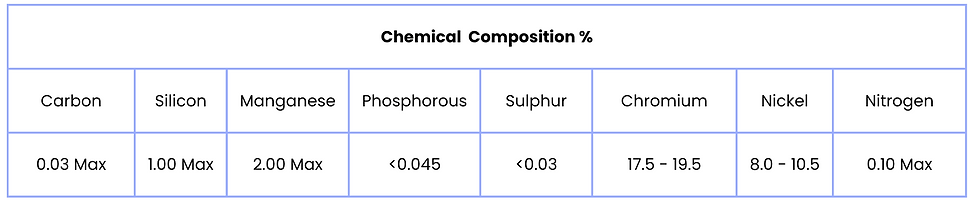

SS304L stainless steel is a low-carbon version of the widely used SS304 grade, designed to offer excellent corrosion resistance while minimizing the risk of intergranular corrosion during welding or high-temperature exposure. Its low carbon content (≤ 0.03%) makes it ideal for welded structures where post-weld heat treatment is not feasible. SS304L maintains good strength, high ductility, and excellent toughness across a broad temperature range, including cryogenic conditions. It is non-magnetic in the annealed state but may become slightly magnetic after cold working. This steel is widely used in chemical, food processing, pharmaceutical, and architectural applications due to its versatility and durability.

Applications

-

Pharmaceutical & Medical Equipment

Ideal for sterile environments requiring non-reactive surfaces.

-

Chemical Processing Equipment

Applied in vessels, piping, and tanks handling mild chemicals.

-

Food & Beverage Industry

Used in tanks, piping, and kitchen equipment for hygienic corrosion resistance.

-

Heat Exchangers & Condensers

Suitable for cooling systems and marine applications in non-aggressive environments.

-

Architectural & Structural Components

Used in railings, claddings, and decorative structures for its clean finish and corrosion resistance.

Manufacturing

Process flow for manufacturing 304L steel

Melting

Ingots melted in AOD, impurities fully killed and followed LRF and VD process at Client's request. Ingots annealed

Forging

Press or Hammer Forged with reduction ratio of 3.5 to 4.5 times

Heat Treatment

Solution annealing cycle post forging or any special QT process as per Client's TDC

Quality Test

Ultrasonic, Hardness, Mechanical, Microstructure testing of the metal at a NABL approved lab

Proof Machining

Proof machining of Forged Rounds and Flats as per Client's requirements

bottom of page